Actual case

The CNC gear machining machine of AGMT has high degree of freedoms, can machining various particular tooth profiles, and has the flexibility of feedback compensation for the precision of the corrected tooth profile.

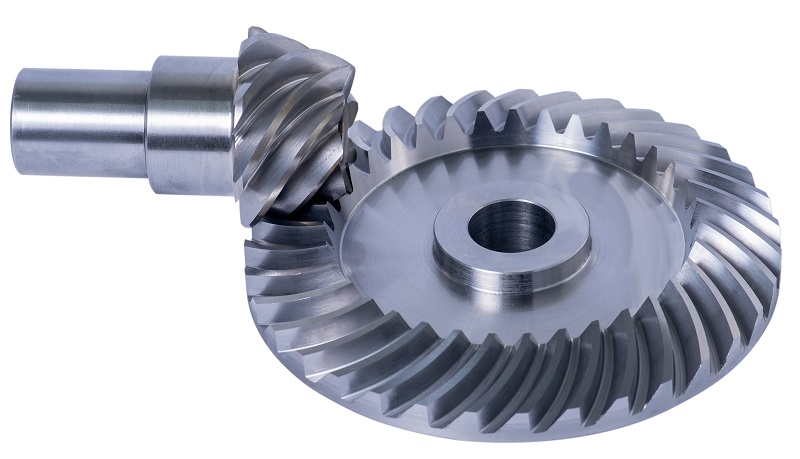

Face-hobbing spiral bevel gear or hypoid gear (constant-teeth depth)

Ultra-high efficiency continuous face-hobbing, the processing module is 4 mm, and it only takes 85 seconds for 35 teeth cutting, and the cycle time is about 1/4 of the face-milling method. The closed-loop manufacturing can be used, and the precision can reach above Din6. Compared with the designed tooth face, the maximum absolute error of the topology is within 0.015mm. This function is the first to be seen in Taiwan's self-made machines. Providing technical services such as tooth cutting, precision cutting, geometric inspection, meshing test and single tooth flank analysis, etc.

Face-milling spiral bevel gear or hypoid gear (non-constant-teeth depth)

Our High-rigidity machine has high-precision cutting, using closed-loop manufacturing, the precision can reach above Din6. Compared with the designed tooth face, the maximum absolute error of the topology is within 0.015mm.

Providing technical services such as gear cutting, grinding, geometric inspection, meshing test and single tooth flank analysis, etc.

Large module spiral bevel gear

Our machine can cut bevel gears with a diameter below 280mm. Because of the high-rigidity of the machine, it can be combined with cutting force optimization to perform high-precision cutting and improve gear cutting efficiency. The precision can reach above Din7, and the maximum absolute error of topology is within 0.02mm compared with the designed tooth face.

Providing technical services such as gear cutting, geometric inspection, meshing test and single tooth flank analysis, etc.

Swivel format face gear

Using bevel gear cutter for cutting, and the tooth face meshing is optimized based on theory. Compared with the general face gear, the overcut and sharpened tooth area can be greatly reduced. Using the bevel gear manufacturing process, it is possible to make tooth face measurement and produce international standard reports. With the closed-loop manufacturing, the precision can reach above Din6. Also, it can be ground and processed to improve the tooth face precision. The cutting process can be adjusted for different materials, including stainless steel, aluminum, copper, medium carbon steel and low carbon alloy steel, etc.

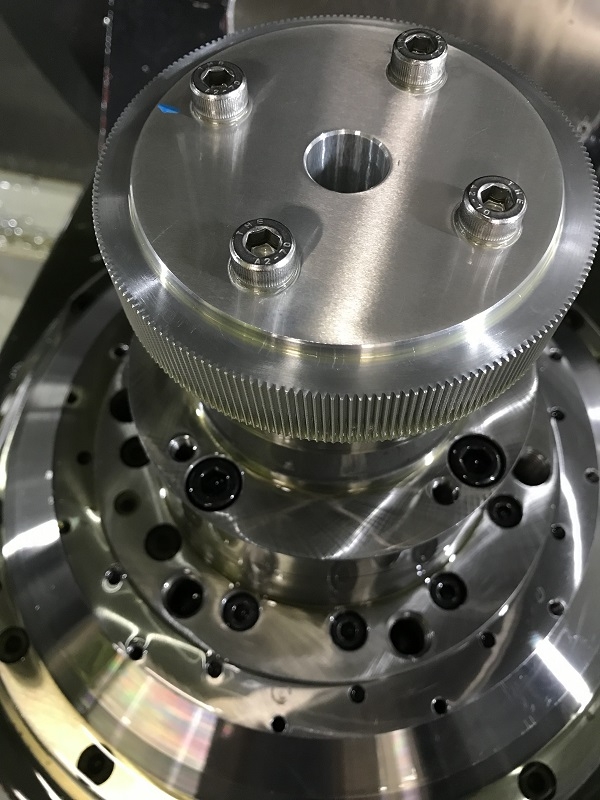

Actual case

Our machine can be applied to the power skiving process of continuous cutting, with a module of less than 2, cylindrical internal and external gears, perform high-efficiency production, and a significant saving of gear cutting time.

Power skiving for internal & external cylindrical gear

Our machine can be applied to the power skiving process of continuous cutting, with a module of less than 2, cylindrical internal and external gears, perform high-efficiency production, and a significant saving of gear cutting time.

Advanced Gear Machine Technology Co., Ltd.

Advanced Gear Machine Technology Co., Ltd.