Gear Technical Services

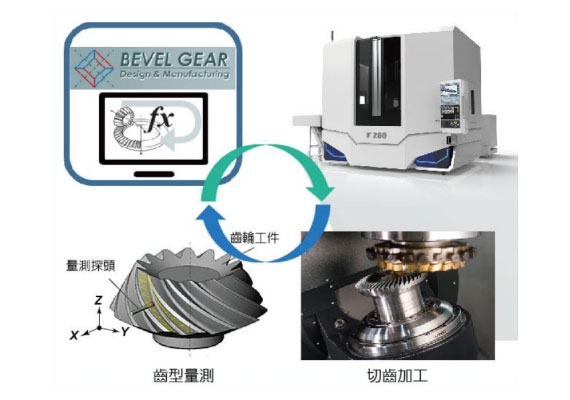

We manage all aspects of gear design,

production and manufacturing function integration. We provide design, topology analysis, measurement, customization (closed-loop manufacturing systems) and sample testing services.

The fully automatic CNC-controlled P40 precision measuring center is designed as a compact unit for the workpiece diameter range up to 400 mm. The machine is used to inspect cylindrical gears, pinion type cutters and shaving cutters, worms and worm wheels, hobs, bevel gears, general dimension, shape, and positional deviations of axially symmetrical workpieces, cam and camshaft measurement and rotor measurement.

1. Detecting tooth profile with measuring instrument

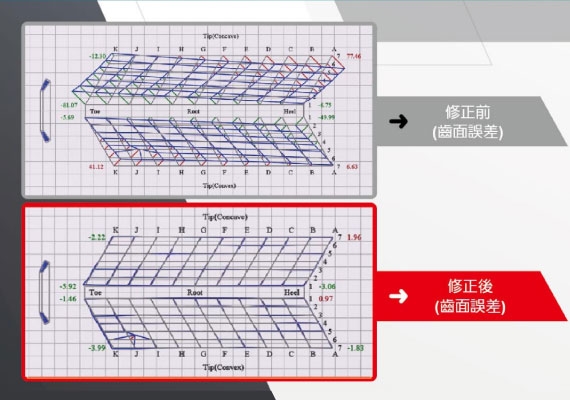

2. Comparing and fixing with the preset tooth profile

3. Output data into machine after compensating tooth profile error

4. Set parameter input

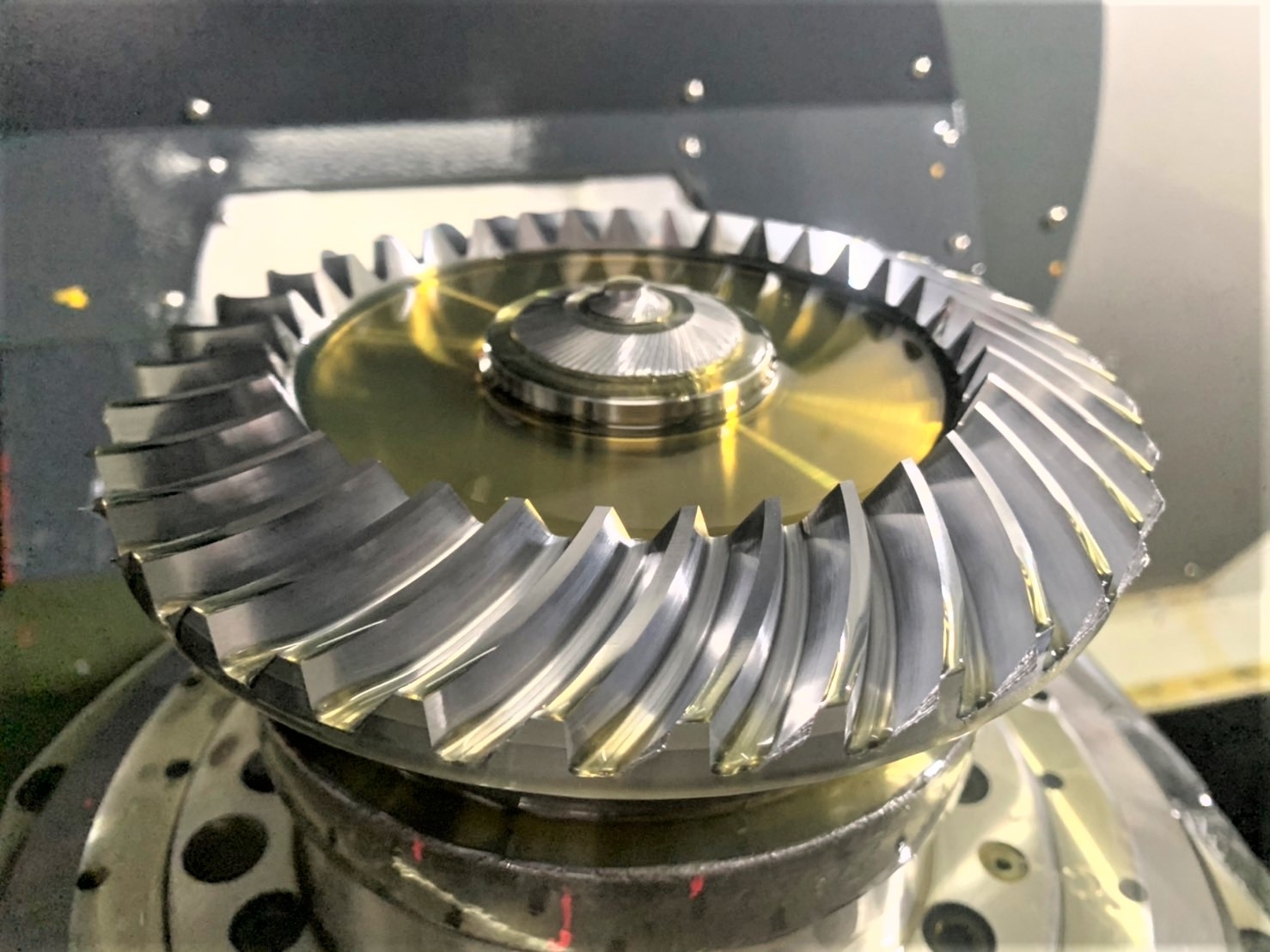

Our professional technicians make sample testing of different gear shapes.

Make sure the high precision of the output gears.

The machine is equipped with a scanning probe

Online tooth alignment and scanning tooth profile error

Precision compensation available(optional)

Spiral bevel gear related calculations (strength and cutter parameters, mechanical settings)

Support our customers for reading computing files and use common format for gear measuring instruments>

Gear blank and 3D gear CAD file export

Gear performances analysis, error compensation

Auxiliary closed-loop manufacturing

Quickly check the actual meshing status of the gear set, clarify the problems of gear machining and gear assembly plant, digitizing the meshing results and record & generate reports, gear meshing grading (DIN, ISO)

Advanced Gear Machine Technology Co., Ltd.

Advanced Gear Machine Technology Co., Ltd.